BUILDING NOTES

Day 1 – Grading 12/11

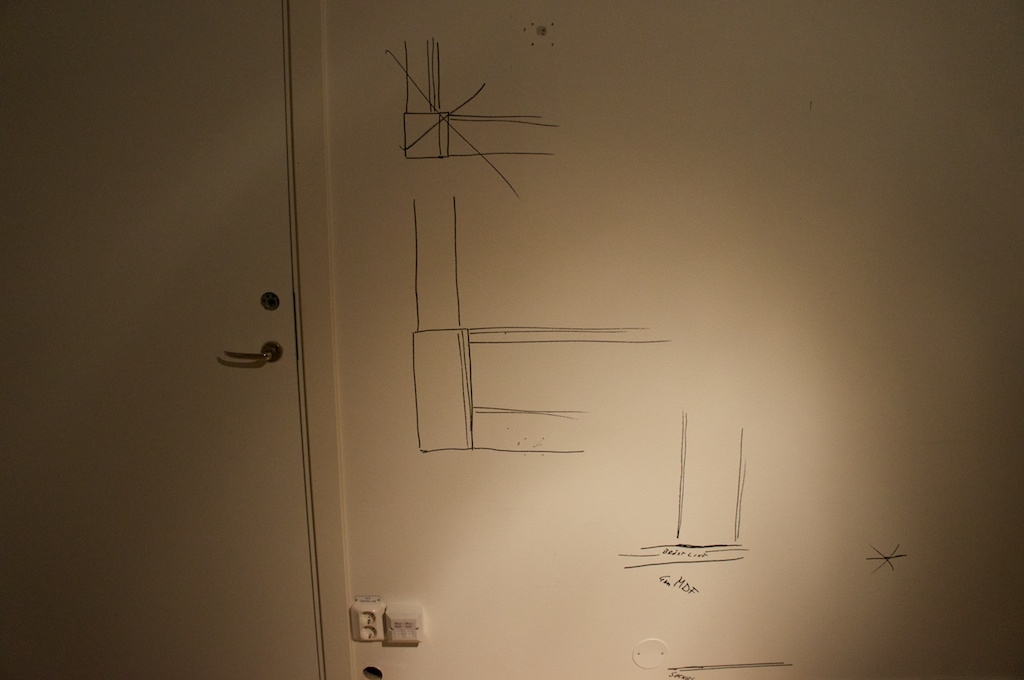

Start at 6am with two carpenters and the floor to the acoustic room in which the grading suite will be built. Move ventilation, electrics and door to corner to get the entrance where I want it.

The plan is to get the room dimensions to 11.5m x 4.9m. The height of the room will be 3.7m.

The building of the acoustic room is planned to take 3 weeks and during that time I will start the construction of the machine room, online room and assist room.

The rest of the rooms are getting ready and cleaned for the building ahead. I have to plan the the construction to sync with the Foley since they are having double shift of productions going.

Day 2 – Grading 13/11

The floating floor in place and starting to raise the walls.

Had meeting with Technical consultant and carpenters about the rest of the rooms. Assigning areas of responsibilities to each involved. My plan is to have the machine room and online room ready for hardware v49.

Need to get a decision about the projector soon.

Day 3 – Grading 14/11 – 15/11 (Night)

The first wall is covered with plaster board and the rest of the walls are coming up.

The carpenters are working night and will end the work week on thursday morning.

The machine room wall facing the grading is now closed up and ready. The small room in the back of the machine room will be a good room for spare parts and cables.

Day 4 – Grading, Machine room, Online, Assist 19/11

Three out of four walls in the grading suit covered with 3 layers of plaster board. We started to plan the building of the machine room and online suite. Moved all furniture out of the way from the online and assist suite to make room for the carpenters. The plan is:

Machine room

Fix the walls with a dado panel, textile parts and plaster to make it look like concrete

Install a window

Change door to a sound proof door

Fix the interior prior to 5pcs rack cabinet installation

Install separate power with circuit breaker box

Install cooling water for cooling rack cabinet

Online suite

Install a window

Change the door so it will open outwards.

Fix the interior prior to work area installation

Assist room

Remove window towards kitchen area

Change the door so it will open outwards to the left instead of right

Prepare for wall mounted monitors

Fix the interior prior to work area installation

Day 5 – Grading, Machine room, Online, Assist 20/11

Changed the doors. Started to make room for the window into the machine room. Discovered a hidden drain pipe from the ventilation room above. Decided to move the window to the right of the pipe and maybe put in a smaller window to the left of the pipe.

In the grading, all walls are in place and the ceiling is starting to come into place. The door is moved to the correct place.

Day 6 – Grading, Machine room, Assist 21/11

Started with ceiling in the grading suite. Had a meeting with the ventilation consultant about cooling to the machine room, grading suite and projector.

Sanded the wooden floor to tone it down in color with oil.

Started to close up the wall between the kitchen area and the assist room.

Day 7 – Grading, Machine room, Assist 22/11

Pause in the grading, the guys needed to do some other job and will not work this day. Ceiling almost done.

Working with the machine room, the windows are being built up. Will be one larger and one smaller to work around the drainage pipe we found in the wall.

Had meeting with ventilation consultant regarding the cooling of projector. I have found more exact specification regarding the projectors need of air flow. 400 m3/hrs. Hopefully the existing ventilation will be enough to handle the airflow and we don’t have to solve a separate solution for this. The cooling for the machine room will be provided by the in-house cold water pipes and a cooling rack from APC.

Day 8 – Machine room, Assist 23/11

The carpenters are working on the rooms. The floor in the machine room is oiled the first time. The plan is to oil it twice to get it darker. The windows are being prepared. We have opened up the ceiling between the machine room and assist room to put in some cabling pipes. 2x70mm pipes for CAT and SDI.

Day 9 – Grading, Machine room, Online 26/11

Carpenters working on windows. Opening up wall for one narrow window into machine room. Window in Online is fitted with glass. The acoustic room in the Grading suite is almost done. Last bits in the ceiling and the box around the pipes are left.

Container outside in place, emptied the online room from debris.

First delivery of technology today. 4 Racks with accessories from Dustin. Carried one into the machine room to check the height.

Day 10 – Grading, Machine room 27/11

Spent all day with consultant from Scheduall, setting up the new booking software.

The ceiling in the grading is covered, all pipes behind plaster

The walls in the machine room are getting in place with the wooden panels. The windows are getting closer to done.